Overview

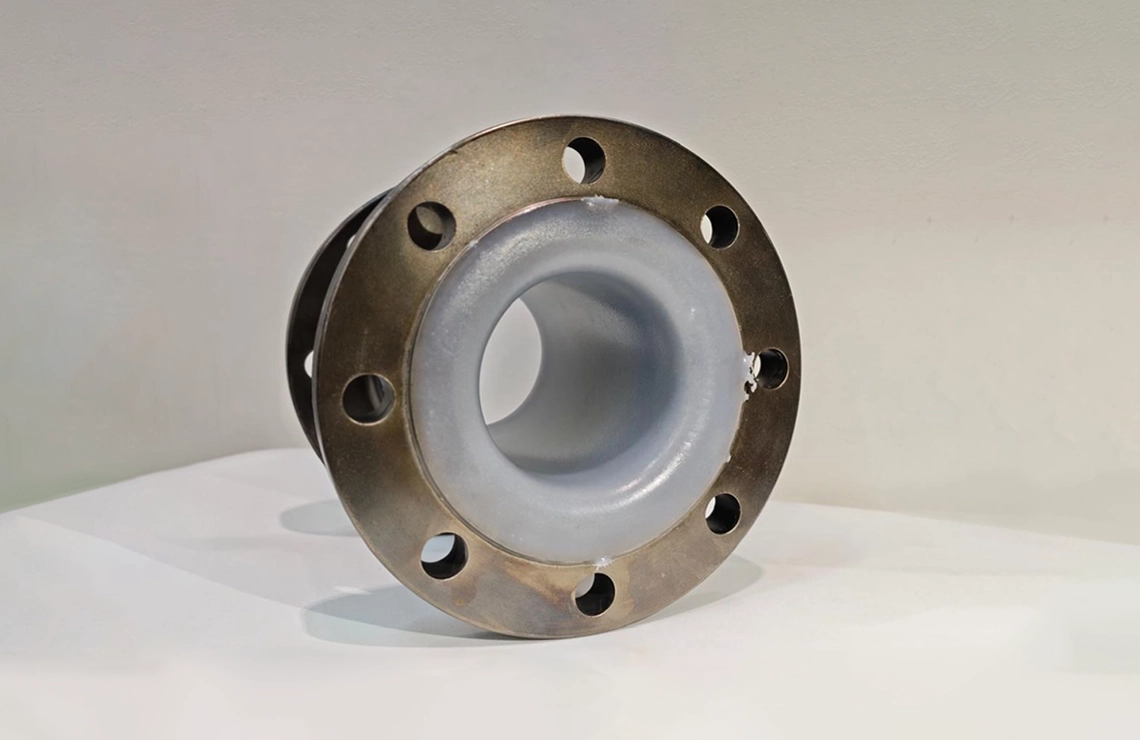

In a continuous pursuit of performance and practicality, PolyStik™ is an innovative chemically modified polyethylene-based material tailored for rotolining – a specialised technique that bonds polymer linings to the internal surfaces of pipes, tanks, and vessels. This lining process creates a protective barrier against corrosion and chemical degradation. While traditional materials like PTFE and ETFE offer outstanding resistance, they are often cost-prohibitive for less demanding applications. PolyStik™ bridges this gap, offering a smart and economical solution for industries seeking moderate resistance with maximum value.